The case is that of a shipyard contracted to design and assemble what we shall call a New Generation Boat (NGB), full of electronics and software. The management has bet on a daring project management process to deliver the ship faster than ever before seen in the history of this industry. Operations started with design, of course, with a big team of engineers working on CAD workstations. The structure was first conceived, followed by industrial systems, hydraulics, electrical circuits, instrumentation and associated electronics and software, and, finally, decoration and on-board life equipment. In record time the structure started being assembled at the shipyard to the satisfaction of the customer. This is when electricians and hydraulics specialists were given their first task lists and started their job. Once a portion of an electrical circuit mounted, it had to be validated by a quality controller. Alas, the latter knowing that hydraulics had to be fitted later with the risk that electrical wires and appliances be dismounted or moved, they refused certifying the electrical installation. And from delay to delay, the situation turned into a backlog of several tens of thousands of work hours and an important postponement of the delivery of the boat. This is when management commissioned a study from us to inquire about the risk of accidents on the assembly line and later malfunctioning of the ship.

How does the assembly line work? Its missions are to assemble and finish the boat’s structure first, to fit and connect on board systems, to test the ship and its functions, to finish and validate each area, to close completed areas, and to deliver the completed ship for tests at sea. Its inputs are ready-to-fit physical sections, subsystems and equipment. It delivers the boat, with all sections put in place, tested, and closed. Resources include managers, engineers, and technicians and support functions as well as layouts, task lists, and tooling. The expected quality and expected performance of the ship stem from putting in place both a dependability assurance model and a best-practice engineering model. Subcontractors from different countries played a major role in the project, each supplying essential elements of the boat and contributing to its assembly at the shipyard.

Beyond this general, theoretical view of the assembly line the shipyard was in a deep crisis due the huge backlog and lateness of the work. Our study was designed in four steps. First, fifteen 45–60 minute in-person interviews with staff representing the various teams and functions involved, using semi-open questions. Each questionnaire was confidential and validated with the interviewee. Secondly, a semantic analysis of collected answers was completed to reveal categories like difficulties, modes of reaction, etc. Findings at this stage were anonymous. Third, an evaluation of this data-processing stage led to identifying key findings, some of which were graphically charted. Finally, conclusions were drawn and presented to the top management.

Five dysfunctions were identified:

- the feeling, or fear, of being undertaken by events;

- the lack of proactive information and transparency in managers and engineers decision making and choices;

- the general lack of rigor in the organization generating non-conformances, derogations, and delays;

- a sense that everyone does whatever they want, from boycotting key meetings to unauthorized dismounting of devices; and

- a tendency to play with circumstances by tossing the hot potato, playing hide and seek behind the incident management information system.

Ten topics emerged from open coding answers:

- partners (subcontractors)

- work ambience

- communication (of managers and engineers)

- scheduling & workload (work planning)

- professionalism

- design of products/processes

- design of workstations/tools

- self-organizing

- prescribed organization

- management

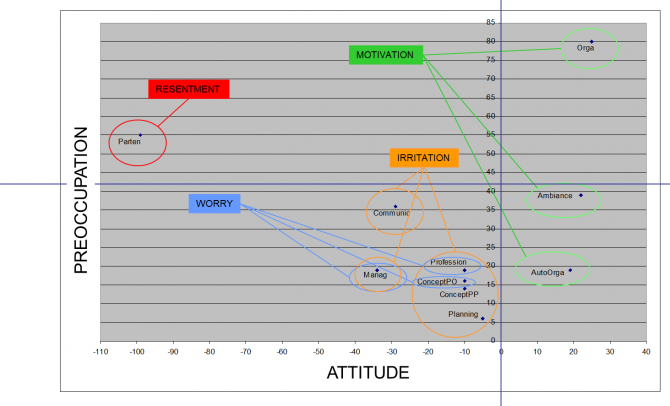

Each one evaluated along two parameters. Preoccupation measured the number of times a topic was mentioned. Attitude measured how interviewees felt about the topic: enthusiasm was rated 10, satisfaction 5, hope 1, indifference 0, dissatisfaction / stress / degradation -5, and discouragement -10. The product of Preoccupation times Attitude measured individuals’ Experience of the topic.

These evaluation results were graphed as follows when summing-up data from the fifteen interviews:

What this diagram shows is four types of experiences:

- Resentment,

- Motivation,

- Irritation, and

- Worry.

People working at the assembly line were motivated by the possibility to self-reorganize themselves to adjust to emerging difficulties in a fairly good ambience while their understanding of the prescribed organization did not stop them from formulating harsh critiques about it.

They were fairly irritated by the management, the lack of transparency and proactiveness of managers and engineers’ communication, the general lack of professionalism, the poor schedule and work planning, as well as both the design of the ship (they did not like the fact that mounting listings were coming at a pace that prevented the validation of work done by quality controllers) and the design of their workstations and tools (for instance, they voiced their disdain for having to walk along safety paths, as it slowed them down).

Some of these same factors worried them (management, product design, and workstations design) as they felt they might trigger an incident and possibly fatalities in a context of huge pressure.

Finally, they frankly resented subcontractors (partners) as they blamed many difficulties on them (for instance their lack of professionalism).

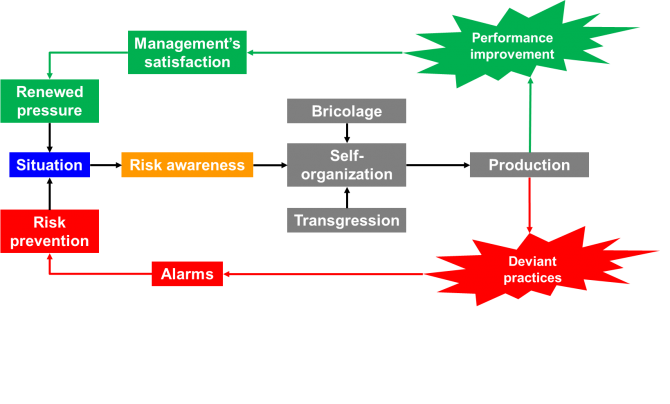

The finding on which we can focus here is these people’s taste for self-organization. This phenomenon, well studied in research on Highly Reliable Organizations (HRO) since, for instance in Managing Risk and Reliability of Process Plants by Mark Tweeddale, results from the conjunction of high pressure and failure of the prescribed organization—whether the performance and dependability models mentioned earlier or prescribed security and safety rules.[2] This adverse deviation of prescribed working conditions pushes people to adopt ad hoc practices that help them turn around difficulties and solve them.

On the one hand, the perceived failure of prescribed operating procedures challenges the success of the project (i.e. building this very daring new generation boat). On the other hand, the perception of growing risks—for instance of incidents that might affect workers—yields a need for homeostasis, for a return to some form of nominal comfort and safety.

In the first case, teams, and not just individuals, collectively do what Karl Weick in his famous article “The Collapse of Sensemaking in Organizations: The Mann Gulch Disaster,” describes as “bricolage,” the faculty to improvise reactions by instrumenting any single artifact, people, or available possibility into a solution to problems of the moment.[3] In the second case, transgressing prescribed rules appears as the counterpart of bricolage as it frees individuals and groups from the rulings of the hierarchy.

The resilience of work units under heavy pressure derives from both bricolage and transgression.

This comes at a potential cost anyway: new risks. While the work unit’s resilience maintains workers in good dispositions, arrangements they make create satisfaction among the management who sees that the backlog, in the present case, is being reduced out of everyone’s efforts. In parallel, they raise fears among risk managers who see in the situation emerging threats to workers’ safety and possibly to the boat’s dependability.

The following diagram details the joint process of self-organization, management satisfaction, and attempted risk regulation:

While the management’s decisions to keep the pressure on teams results from performance improvements, risk managers, alarmed by incidents or near-misses, try to prevent further risks.

Five lessons can be drawn from this real life case:

- Individual resilience in action is required, as without it Work Unit Resilience would not happen at all; people would be overwhelmed by adverse circumstances. Individual resilience starts with the awareness of risks and relies upon the faculty to find solutions to daily difficulties by instrumenting either people or artifacts. Training, or at least informing, staff beforehand to be resilient in crisis situations is vital.

- Self-organization contributes to mission (business) resilience. Should work units’ sense of community or strengths leave them, this would terminate any effort of the overall organization to surmount adversity. Should the management prevent any such practices in the name of doctrinal points of view about how processes have to function, this would be inappropriate. Do not reject the idea that people will distort prescribed procedures in the face of adversity.

- Precise margins of maneuver are needed to allow self-organization. Whether they are the spontaneous fact of toxic handlers and compassion within the organization or of carefully crafted liberties or resources meant for crisis times, margins of maneuver are a key element of business and work unit resilience. It is also always found in territorial resilience when catastrophes strike populations: social networks, reliance on community leaders, extra resources and spare equipment, etc.

- Self-organization creates new risks. In fact, this has been a big question in HRO research and it always stands true that any action we take is double-faced, with both a positive and a (potentially) negative side.

- The management needs to monitor carefully and regulate self-organization phenomena when they happen (and they always occur in adverse situations as this is the only way for people to get through such circumstances). In practice, this means having people embedded in work units to observe and report situations and adaptations taking place in crises. Their reports must be taken seriously and reactions must be quick and smart. Like work units’ behavior may be flexible, the management’s reactions have to be adaptive and fast.

References

[1] Paul Theron, “Key Enablers of ‘Organizations’ Resilience,’” Linkedin.com, July 28, 2016, http://www.linkedin.com/pulse/key-enablers-organisations-resilience-paul-theron-phd-fbci?trk=mp-author-card.

[2] Mark Tweeddale, Managing Risk and Reliability of Process Plants (Burlington, Mass.: Elsevier Science, 2003).

[3] Karl Weick, “The Collapse of Sensemaking in Organizations: The Mann Gulch Disaster.” Administrative Science Quarterly 38, no. 4 (1993): 628-52, http://www00.unibg.it/dati/corsi/37173/61536-The%20Mann%20Gulch%20disaster%20-%20The%20collapse%20of%20sensemaking%20in%20organizations.pdf.